What are 4D Number Plates?

To understand as to why and ‘how are 4D number plates made’, we need to understand what 4D Number Plates are and a brief history of number plates in general.

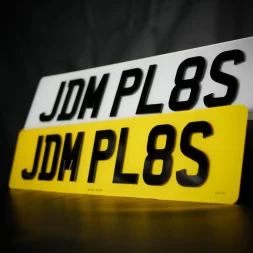

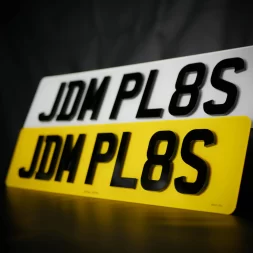

4D Number Plates, a recent craze amongst thousands of car enthusiasts within recent years. 4D plates are a type of vehicle registration plate that uses three-dimensional characters rather than the traditional two-dimensional printed characters.

4D number plates are made by applying three-dimensional laser cut acrylic characters onto the plate using industry standard adhesive, which gives them a raised, three-dimensional appearance. 4D number plates are becoming increasing popular – initially purchased by enthusiasts to modify and personalise the appearance of their vehicle – now being purchased by a vast range of people to give an extra bit of personalisation to their pride and joy!

These number plates generally come with raised letters of 3mm thick although 5mm thick 4D plates are popular. At JDM Plates, we can manufacture 3mm and 5mm thick acrylic letters

Brief History of Number Plates

UK registration plates, also known as license plates or number plates, are issued by the Driver and Vehicle Licensing Agency (DVLA) and are used to identify vehicles on the road. The current system of registration plates in the UK has been in place since September 2001, but the history of UK registration plates goes back much further.

The first registration plates in the UK were introduced in 1903, when the Motor Car Act required all motor vehicles to be registered and to display a registration plate. These early plates were made of metal and consisted of two letters followed by up to four numbers. The letters were chosen by the owner of the vehicle, and the numbers were assigned by the local council.

These letters and numbers we’re typically embossed which appeared three-dimensional. These were produced by hydraulic machines which pressed the registration number into the metal plate generating the embossed effect. These number plates were generally black with silver embossed letters.

Over time, the system of registration plates has evolved to include more letters and numbers, and the format of the plates has changed to include different colours and designs. In the 1960s, the system was changed to include an age identifier, which consists of a single letter that indicates the year in which the vehicle was registered. This was introduced to help law enforcement agencies identify the age of vehicles and to enforce laws related to vehicle emissions.

In the current system, registration plates consist of two letters, followed by two numbers, and then three letters. The first two letters indicate the location where the vehicle was first registered, and the second two numbers indicate the age of the vehicle. The final three letters are chosen by the owner of the vehicle.

As time went on and new vehicles were manufactured, Government released modern legislation and updated number plate requirements; some of these requirements included that number plates needed to made of a specific material with specific colours – black lettering on a white background for the front and yellow background for the rear number plate.

To meet these requirements, British Standards were set and the British Number Plates Manufacturing Association (BNMA) was required to comply with these standards. The BNMA then concluded that all new number plates need to be printed using specific printers onto specific reflective material along with specific acrylic or substrate. The standard was set.

Technologies required to produce 4D number plates

You’re probably reading this and thinking, so how are 4D number plates made?! Well, we’re getting to that…

As newer technologies advanced, newer products were being manufactured. 3D printers and laser cutters were pretty expensive and as the prices started to drop around 2016-17, hobbyists and enthusiasts started to consume and purchase these high ends machines to use for everyday DIY projects.

A laser cutter is a machine that uses a laser beam to cut materials, such as wood, metal, or plastic. It works by directing the laser beam at the material, which is then vaporized or cut according to the specific design that has been programmed into the machine. Laser cutters can be used to create precise and intricate designs, and they are often used in manufacturing, prototyping, and other industrial applications. They can also be used by artists and hobbyists to create a wide range of projects, such as jewellery, crafts, and other decorative items.

CAD/CAM is the engineering term used. We have an article explaining what is a laser cutter and how they operate if it interests you.

This refers to computer aided design and computer aided manufacturing. The computer aided design in this instance refers to the design of the font for the lettering that is to be laser cut. This would essentially be 2D-design software.

Computer aided manufacture is the laser cutting machine which is being controlled by the computer. The computer which utilises the software, controls the laser cutter co-ordinates, on and X-Y axis to ensure the laser cutter beam cuts precisely where it needs to.

Custom signage, personalized laser engraved products and a vast range of other ideas started taking shape and therefore small businesses revolving around the aforementioned niches started to explode and gain momentum; this is when the birth of the 4D number plate hype began and it introduced the catalyst of 4D number plates and answered the unasked question of how are 4D number plates made.

How are 4D Number Plates Made?

With the correct technologies and correct fundamentals in place, it is fairly simple to manufacture a 4D number plate. Below is a breakdown of the process, and the answer to the question, ‘How are 4D number plates made’, for a standard size UK number plate (this is assuming all materials are in stock):-

- Gather your materials; this will be the laser cut 4D letters, clear acrylic and coloured reflective. If making a pair of 4d number plates then 2 pieces of acrylic is required and both white and yellow reflective is required.

- Open the number plate software. This is typically sourced from a member of the BNMA (mentioned above) and once accessed, type out the registration number including the space which is legally required and print. Ensure documents have been received and that the required legal markings are printed along the bottom of the number plate.

- After the print has been successful. It is time to roll the reflective through a high pressure roller along with the PMMA number plate acrylic. This process produces a generic two-dimensional printed number plate.

- These next steps are where the magic happens and where the 4D number plate comes to life!

a. Using a jig, stencil or even by hand, remove the liner from the adhesive side of the 4D letter.

b. Carefully, either by hand or using a special purpose designed number plate jig, place the 4D letter onto the number plate and press firmly so the adhesive bonds to the surface of the number plate.

c. Repeat the step above for the remaining letters and numbers and once complete, roll the number plate through the previously mentioned high-pressure roller to ensure the letters are completely bonded to the number plate.

d. If required, remove the protective layer on the acrylic letters and voila, your 4D number plates have been made.

e. Bonus step, to give that extra shine, feel free to spray a quick detailer onto the surface of the number plate and wipe away. This will give an additional glossy shine to the finish of the completed set of 4D plates.

Sit back and admire… You now know the answer to ‘How are 4D number plates made’.

Get your 4D number plates from JDM Plates today

Now that you have a brief guide as to how are 4D number plates made, why not try and manufacture some yourself? Alternatively, which may be a better idea, why not buy your next set of 4D number plates from JDM Plates?

Choose from a selection of products below:

-

Sale!

4D 3mm Number Plates For All Vehicles

Rated 4.87 out of 5£24.99 – £70.99 inc. VAT This product has multiple variants. The options may be chosen on the product page -

4D 3mm Import Number Plates For JDM Vehicles

Rated 4.88 out of 5£24.99 – £70.99 inc. VAT This product has multiple variants. The options may be chosen on the product page -

4D 5mm Import Number Plates For JDM Vehicles

Rated 5.00 out of 5£27.99 – £71.99 inc. VAT This product has multiple variants. The options may be chosen on the product page -

4D 5mm Number Plates For All Vehicles

£27.99 – £71.99 inc. VAT This product has multiple variants. The options may be chosen on the product page

JDM Plates are number plate experts. We specialise in all styles of number plates and offer some of the smallest legal sizes within the UK utilising our state of the art laser cutting technology. Not only this, but rest assured, the quality of our number plates is second to none so if you’re in the market, feel free to design your next set of number plates using our visual builder.

Not only this, but JDM Plates have one of the best Trustpilot review profiles in the UK for number plates. We are Experts, an Authority within the industry and can be trusted.